Preparing a surface for construction work or general maintenance is an essential part of any successful project. It helps ensure that the surface is suitable for the materials being laid or re-coated and can even help make the project easier to work with. In this article, we’ll discuss the importance of surface preparation and how it can benefit construction workers.

The various industries utilising surface preparation equipment and techniques

Construction

In construction, preparing the surface before applying any replacement materials is essential to the project’s success. This includes preparing the ground for foundation work, as well as prepping floors, walls and ceilings for painting or further construction. Failing to prepare the surface properly can result in subpar work, or even damage to the materials being laid.

Additional applications include preparing pre-cast concrete slabs and panels in readiness for assembly and texturising dry concrete in between concrete “pours” during the active bridge, roadway, platforms or infrastructure projects.

Automotive

In the automotive industry, surface preparation is crucial for paint and bodywork. If the surface isn’t properly prepared, the application of new coating protection coating or paint will suffer. Essentially, pre-weld surface preparation and post-weld cleanse is a critical part of the integrity of automotive applications. This can be anything from dirt and debris on the surface to oxidation and rust. To get a perfect paint finish, the surface must be meticulously prepped.

Marine

Surface preparation is just as important in the marine industry as it is in any other. In fact, it might even be more important given the harsher environments that marine vessels operate in. Without proper surface preparation, marine vessels would be susceptible to corrosion, fouling, premature ageing, environmental fines or significant repair costs if unmanaged.

To protect marine vessels from these dangers, shipyards and boatyards regularly rely on surface preparation solutions. This typically involves sandblasting or using high-pressure water jets to clean the vessel’s hull whilst a vessel is decommissioned in a dry dock. However, it is extremely expensive (whilst effective) to decommission a vessel to undertake this task.

During service at sea, it is essential to deploy continuous management of onboard corrosion or specifically when the vessel ownership or cargo may change.

Vessels have to be maintained to a high standard of preparation to be allowed to enter international posts due to the risk of the negative environmental impact of a poorly maintained vessel in local waters. Surface preparation is, therefore, critical to achieving these operational standards.

Oil & Gas

Oil and gas refineries are some of the most unforgiving environments for equipment. The extreme temperatures, caustic chemicals and high pressures take their toll on even the most well-built machinery. To keep equipment running smoothly and efficiently, regular surface preparation is essential.

Surface preparation involves removing all the dirt, grime, protective coatings, rust and corrosion that has built up on the surface of the equipment. This can be done through various methods, including media or water blasting/jetting, power washing and chemical cleaning. By regularly cleaning and preparing the equipment, operators can extend its lifespan and keep it running at peak efficiency.

Due to the high risk of explosion environments, standards such as ATEX are required on all tools and equipment used on board vessels or platforms, which certifies a product as “no-spark”, eg; they are not likely to ignite a fire or cause an explosion.

Different types of surface preparation techniques

Concrete preparation

Surface preparation is a key step in any concrete preparation project. It is important to ensure that the concrete surface is clean and in good condition before any coating, covering or additional concrete is applied. This means removing any dirt, debris, or other contaminants from the surface, as well as repairing any cracks or other damage. The concrete texture is critical to the construction process, whereby smoothing the surface or texturising the surface may be desired. See information on CSP surface roughness for more information: 7 Concrete Surface Roughness Measurement Methods.

Removal of excess concrete depth due to “Carbonisation” is an essential activity included in surface preparation in the construction industry. Expert advice is always required under such circumstances, however, multiple solutions are available in the surface preparation tool genre to rectify such issues.

Recommended tools:

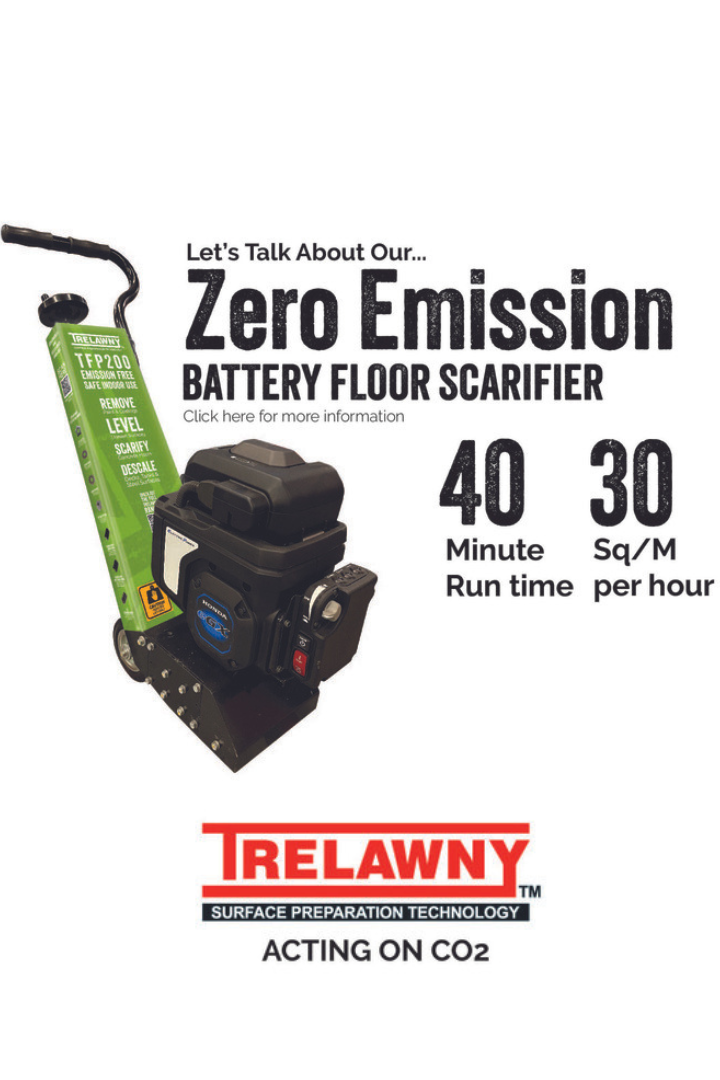

- Floor machines – Floor scarifier,

- Scabbling and Floor Scabbling – Products – Trelawny (trelawnyspt.com)

- Floor Grinding – Floor grinder

Coatings removal

Surface preparation tools are an essential part of the process of removing coatings, corrosion, and other accumulated materials from metal surfaces, especially in the Marine, industrial and Automotive industries. There are a variety of tools available for this purpose, including scarifying, scabbling, grinding, abrasive blasting equipment, and chemical strippers. In most cases, the most appropriate tool for the job will depend on the type of material to be removed and the surface condition.

Descaling and Scabbling machines are best for removing localised rust or other corrosion from a metal surface, while abrasive blasting equipment is more suitable for removing paint and other coatings from larger metal areas. Chemical strippers are also useful for removing accumulated dirt and grime from metal surfaces but require numerous risk assessments and PPE to be worn. It is important to use the correct type of tool when prepping a metal surface, as using the wrong one could damage the surface or cause further corrosion or discolouration.

Recommended tools:

- Needle Scaler & Chisel Scalers – Needle & Chisel Scalers

- Scabblers – Products – Trelawny (trelawnyspt.com)

- Strippers – Products – Trelawny (trelawnyspt.com)

- Scarifiers & Grinders – Floor Machines such as Grinders, Scarifiers

Descaling and surface stripping

Descaling and surface preparation tools are perfect for any industrial, marine, or construction application that requires weld preparation, rust and oxide removal, scale removal, old paint removal, tough coating removal, floor paint/coating removal, and concrete scarifying.

These pneumatic tools are well-suited for heavy-duty applications because they are designed to work quickly and efficiently. Additionally, they can be used with various materials and surfaces, making them versatile and suitable for various needs. They are also highly durable to stand up to the wear and tear of intense use. So whether you’re looking for a tool for removing rust or for scarifying concrete, descaling and surface preparation tools are the perfect solutions.

Recommended tools:

- Floor Machines such as Grinders, Scarifiers

- Scabblers & deck planars & deck hammers- Products – Trelawny (trelawnyspt.com)

Dust control and extraction

All surface preparation tasks create dust from activities like demolition, grinding, drilling, sanding, sawing and chasing. This dust can be both a health hazard and an environmental hazard, so it is important to have effective dust suppression systems in place. Fortunately, there are a variety of dust control machines and equipment available to help keep the air clean. These machines can be used to capture dust particles at their source before they are released into the air.

In addition, some systems use water to create a mist that helps to keep dust particles from becoming airborne. With the right dust suppression equipment, construction sites can be made much safer and more environmentally friendly.

Recommended tools:

In conclusion, surface preparation is essential for achieving the desired results in any project. Without the proper preparation of surfaces, the materials used may not adhere correctly, and the overall performance of the project will suffer. Specialised surface preparation equipment is the best way to ensure that surfaces are ready for the application of materials. This equipment is designed to clean and smooth surfaces, removing any contaminants that could affect adhesion and performance. By taking the time to prepare surfaces properly, you can be sure that your project will be successful.