Client Name:

Di Environment

Client Name:

Di Environment  Project Aim:

Removal of lead/asbestos coating

Project Aim:

Removal of lead/asbestos coating  Tool:

VL303 NEEDLE SCALERS & LONG REACH LITE

Tool:

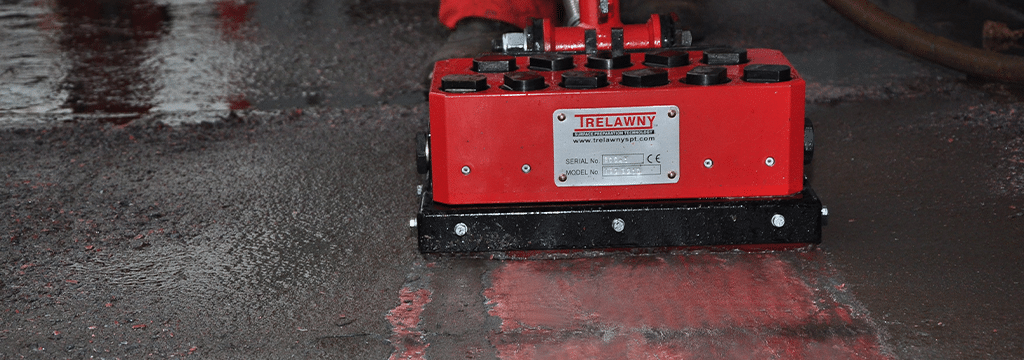

VL303 NEEDLE SCALERS & LONG REACH LITE Specialist Asbestos Abatement contractor DI Environment contacted Trelawny to assist with the removal of contaminated paint from IPN steel beams at a Paris railway station. The 52 beams required the removal and disposal of all lead and asbestos coatings before re-coating with an Intumescent paint providing passive fire protection to the station’s internal steel structure.

The job posed numerous challenges as a result of being at an active railway station in the heart of Paris. Limited time and the need to contain all harmful dust led DI Environment to look for a mechanical solution to remove the coatings before a final blast clean to SA2.5. DI Environment considered power tool cleaning as a viable solution to remove the coatings but were aware of the significant risk of Vibration related injuries from using traditional power tools. This led them to Trelawny’s Vibro Lo™ (VL) range of vibration reduced needle scalers.

The VL range of needle scalers are specially engineered to reduce harmful levels of vibration by up to 8 times that of equivalent non vibration damped tools. The VL303 needle scaler emits vibration levels of just 2.3 m/s2 allowing operators to potentially use the tools for full 8 hour shifts versus less than 20 minutes trigger time allowed with non VL tools.

Alongside the VL303 DI Environment used the Trelawny Long Reach Scrapers (LRS) to remove de-laminated paint and corrosion. The specified LRS-5 “LITE” pneumatic scraper was chosen for its lightweight aluminium construction allowing the operator to easily scrape, chip and de-scale hard to access areas at height.

“TRELAWNYS TOOLS WERE VERY EFFECTIVE COMPARED TO OTHER TOOLS WE TRIALLED, THE LOW VIBRATIONS OF THE VL303 NEEDLE SCALER ARE REALLY LOW ALLOWING FOR INTENSIVE USE”

“PRODUCTIVITY HAS EXCEEDED OUR EXPECTATIONS. THE TOOLS ARE VERY ROBUST. WE HAD A HIGHER YIELD WHICH INCREASED OUR USUAL PRODUCTIVITY BY 50%.”

JS Group Works Manager

DI Environment

Key Facts

- Limited time to remove old coatings

- 2 existing coatings to be removed, a rust proof Lead based paint and a second coating containing Asbestos

- All contaminated coatings to be completely removed, contained and safely disposed

- Unable to blast to remove existing coatings due to containment of dust

- The tight time scale afforded no time for breakdowns

- Intumescent coating to be applied in 7 layers of 700 microns thickness each

Benefits of VL303

- Low air consumption allowing more tools to be used simultaneously

- Low vibration allowing far extended trigger time, reducing operator fatigue, lowering manpower costs and downtime

- Highly productive

- Optional TVS dust shroud for containing contaminated coatings

- Reliable and designed for continuous operation

- Lightweight aluminium reducing fatigue

- 5ft length eliminating over-reaching

- Multiple attachment options