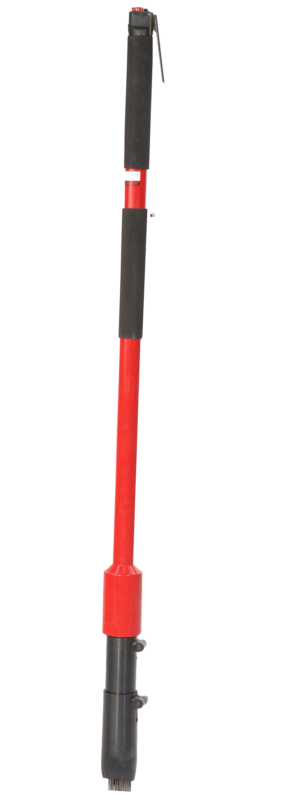

VL LRS55 POLE TAMPER

VL LRS55 POLE TAMPER

The VL LRS55 Pole tamper is a unique tool specifically designed for small area reinstatement tasks. Developed in association with utility companies and conforming with the New Roads and Streets Works Act (UK), it is perfect for water, electric and gas companies. The unique Vibro-Lo™ vibration damping system not only helps to protect the operator from vibration related injury it also ensures maximum control when working in tight, narrow trenches and around delicate utilities.

- Replaceable pin fit compactor feet

- Unique vibration dampening system

- Angled air inlet to direct hose away from operator

- Hand guard to protect operator

- Secondary handle for improved controllability

- Lightweight and compact

- Small reinstatement around water meters and stopcocks

- Narrow trench work carried out by cable companies

- Compaction of tarmacadam or asphalt

- Compacting close to walls and street fittings Back fill small areas

- HAUC Compliant compacts up to 2.19 tonnes/m3 Suitable for pathways & highway re-instatement

FEATURED HEALTH & SAFETY BENEFITS

A low vibration tool designed for small area re-instatement tasks in and around restricted excavations.

Description

Trelawny’s TFP & TCG ranges offer the option for you to brand the machine however you’d like. Stand out by using our vinyl wrap service to promote your brand and upsell other products in your range.

We’ll design your machine and work with you to include all elements available:

- Logo

- Website

- QR code to training guide

- Cross-sell products in your range

- Upsell consumables and spares

- Promote safety aspects

Key Specifications

| Part Number | 150.5331 |

| Weight (kg) | 21.5 |

| Length (mm) | 1270 |

| Blows Per Min (BPM) | 1300 |

| Air Consumption (lps – cfm) | 11.6 – 24 |

| Air Pressure | 6.2 bar (90 psi) |

| Air Inlet | (1/2″ BSP Air Inlet) |

| Vibration level (Aeq m/s2) Primary | 3.5 |

| Vibration level (Aeq m/s2) Secondary | 2.9 |

| Sound Pressure Level | 98.0 |

| Part Number | 150.5330 |

| Weight (kg) | 21.5 |

| Length (mm) | 1270 |

| Blows Per Min (BPM) | 1300 |

| Air Consumption (lps – cfm) | 11.6 – 24 |

| Air Pressure | 6.2 bar (90 psi) |

| Air Inlet | (1/2″ BSP Air Inlet) |

| Vibration level (Aeq m/s2) Primary | Compactor: 3.5m/s² (K= -0% + 40%) |

| Vibration level (Aeq m/s2) Secondary | Compactor: 2.9m/s² (K= -0% +40%) |

| Sound Pressure Level | 98.0db(A) |

| Part Number | 150.5335 |

| Weight (kg) | 21.5 |

| Length (mm) | 1270 |

| Blows Per Min (BPM) | 1300 |

| Air Consumption (lps – cfm) | 11.6 – 24 |

| Air Pressure | 6.2 bar (90 psi) |

| Air Inlet | (1/2″ BSP Air Inlet) |

| Vibration level (Aeq m/s2) Primary | 3.5 |

| Vibration level (Aeq m/s2) Secondary | 2.9 |

| Sound Pressure Level | 98.0 |

| Part Number | 150.5430 |

| Weight (kg) | 21.5 |

| Length (mm) | 1670 |

| Blows Per Min (BPM) | 1300 |

| Air Consumption (lps – cfm) | 11.6 – 24 |

| Air Pressure | 6.2 bar (90 psi) |

| Air Inlet | (1/2″ BSP Air Inlet) |

| Vibration level (Aeq m/s2) Primary | 3.5 |

| Vibration level (Aeq m/s2) Secondary | 2.9 |

| Sound Pressure Level | 98.0 |

Accessories & Consumables

| Image | Part Number | Description |

|

450.5017 | Round Foot Compactor – 127 mm (5” Round)

Pin fit |

|

450.5011 | Square Foot Compactor – 100 x 100mm (4” x 4”)

Pin fit |

|

450.5013 | Compactor Foot – 152 x 127mm

(6” x 5”) Pin fit |

|

450.5016 | Compactor Foot – 100 x 200mm

(4” x 8”) Pin fit |

|

446.5000 | VL LRS55 Service Kit

Consists of: – Valve Spring, Valve Seat O’Ring, Throttle Lever Roll Pin, Thrust Ring, Circlip, Spring, (1each) – Piston O’Ring, Wiper Seal, Valve Stem O’Ring, Piston Roll Pin (1 each) – Locking Pin, Centre Bar O’Ring (2 each) |

| Image | Part Number | Description |

|

815.5550 | Whip Check |

|

859.1580 | ¾’’ BSP Inline Lubricator |

|

458.1580 | Whip Hose & Oiler Assembly

Consists of whip hose, whip check and ¾’’ lubricator |

|

843.0752 | ¾’’ Air Hose

Complete with couplings 15m length |