TFP200 FLOOR SCARIFIER

TFP200 FLOOR SCARIFIER

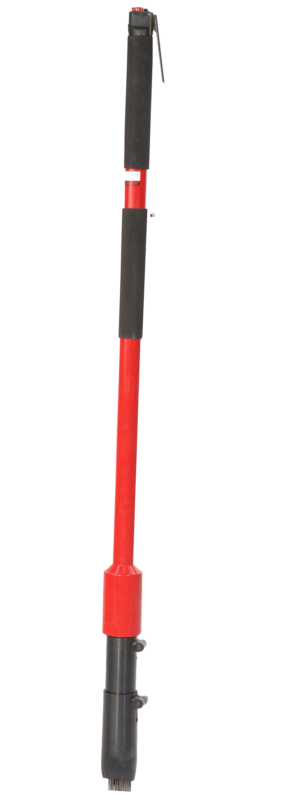

The smallest in the TFP range of scarifiers, the TFP200 is perfect for small to medium jobs. The rigid steel chassis ensures a strong, stable machine suitable for accurate surface preparation of concrete and steel surfaces, removing coatings, levelling and texturing. The TFP200 has undergone a number of changes recently, as part of Trelawny's continual product improvement program. The changes include a new rear-mounted starter box enclosure and plug location, offering greater protection from accidental damage and improved safety to this area of the machine. A new handle-mounted push-button system with an isolation safety switch makes starting and operating the machines even easier than before. A fresh new look and colour scheme has also been introduced with a heavy-duty vinyl wrap system, allowing Trelawny to offer bespoke branded machines to OEM customers & hire companies wanting their own branding on their machines. Retaining all the power, performance and quality customers have come to expect from TFP range.

- Suitable when manoeuvrability is important

- Removal of hard coatings

- Levelling and removing layers of hard materials such as concrete

- Removing painted lines

- Grooving and texturing concrete

- Removal of coatings and scale from steel surfaces

- 200mm cutting width

- Easy to use, maintain and manoeuvre

- Rear mounted electrical switchgear utilizing vibration resistant components

- Precise screw type cutter height adjustment for accurate removal and milling

- Angled dust port allows connection of industrial dust collector, giving virtually dust free performance

- Choice of electric, petrol and pneumatic power sources for operation in a wide range of applications

FEATURED HEALTH & SAFETY BENEFITS

The Trelawny TFP200 is a durable machine suitable for accurate surface preparation of concrete and steel surfaces.

Description

Trelawny’s TFP & TCG ranges offer the option for you to brand the machine however you’d like. stand out by using our vinyl wrap service to promote your brand and upsell other products in your range.

we’ll design your machine and work with you to include all elements available:

- Logo

- Website

- QR code to training guide

- Cross-sell products in your range

- Upsell consumables and spares

- Promote safety aspects

Key Specifications

| Part Number | 320.2400T |

| Height (mm) | 900 |

| Width | 350 |

| Length (Working Position) | 900 |

| Cutting width (Dependent on Cutters) | 195 |

| Cutter head speed | 1833 rpm |

| Working distance from wall | 55mm |

| Weight (Dependent on power unit) | 64kg |

| Engine Type | Honda GX160 Petrol |

| Petrol Power unit | 5.5hp Honda |

| Approximate Fuel Consumption | 1.32 litre per hour |

| Power (HP- kW) | 5.5 – 4.1 |

| Vibration Levels | 6.9 |

| Maximum Cutting Depth (mm) | 3 |

| Vacuum Take off Diameter (mm) | 50 |

| Vibration at Handlebar (Petrol Engine) | |

| TCT Cutters (concrete) | 6.9m/s2 (K=+1.25m/s2) |

| TCT Cutters (steel) | 7.6m/s2 (K=+0.46m/s2) |

| Star Cutters (concrete) | 8.2m/s2 (K=+2.62m/s2) |

| Star Cutters (steel) | 9.5m/s2 (K=+0.65m/s2) |

| Beam Cutters (concrete) | 13.0m/s2 (K=+1.42m/s2) |

| Beam Cutters (steel) | 12.2m/s2 (K=+1.05m/s2) |

| Milling Cutters (concrete) | 9.5m/s2 (K=+1.26m/s2) |

| Milling Cutters (steel) | 12.6m/s2 (K=+1.36m/s2) |

| Wire Brush (concrete) | 7.6m/s2 (K=+2.49m/s2) |

| Wire Brush (steel) | 11.9m/s2 (K=+3.16m/s2) |

| Part Number | 320.2402T |

| Height (mm) | 900mm |

| Width | 350 |

| Length (mm) | 900 |

| Cutting width (Dependent on Cutters) (mm) | 195 |

| Cutter head speed | 1650 |

| Working distance from wall | 55 |

| Weight (Dependent on power unit) | 71 |

| Voltage (V) | 110 |

| Cycle (Hz) | 50 |

| Plug Size | 32 Amp 3 pin |

| Transformer Size | 3Kva |

| Cable Size (mm) | 2.5-4 core |

| Cable Length (m) | 15-30m |

| Power (HP- kW) | 3 – 2.2 |

| Vibration Levels | 4.4 |

| Maximum Cutting Depth (mm) | 3 |

| Vacuum Take off Diameter (mm) | 50 |

| Vibration at Handlebar (Electric & Pneumatic Motor) | |

| TCT Cutters (concrete) | 4.4m/s2 (K=+1.43m/s2) |

| TCT Cutters (steel) | 2.9m/s2 (K=+0.63m/s2) |

| Star Cutters (concrete) | 3.7m/s2 (K=+0.7m/s2) |

| Star Cutters (steel) | 3.8m/s2 (K=+0.98m/s2) |

| Beam Cutters (concrete) | 4.8m/s2 (K=+0.79m/s2) |

| Beam Cutters (steel) | 5.4m/s2 (K=+0.9m/s2) |

| Milling Cutters (concrete) | 7.0m/s2 (K=+1.41m/s2) |

| Milling Cutters (steel) | 4.8m/s2 (K=+1.3m/s2) |

| Wire Brush (concrete) | 2.4m/s2 (K=+0.92m/s2) |

| Wire Brush (steel) | 3.8m/s2 (K=0.79m/s2) |

| Part Number | 320.2404T |

| Height (mm) | 900mm |

| Width | 350 |

| Length (mm) | 900 |

| Cutting width (Dependent on Cutters) (mm) | 195 |

| Cutter head speed | 1650 |

| Working distance from wall | 55mm |

| Weight (Dependent on power unit) | 71 |

| Voltage (V) | 230 |

| Cycle (Hz) | 50 / 60 |

| Plug Size | 16 Amp 3 Pin |

| Cable Size (mm) | Min 2.5 core |

| Cable Length (m) | 30 |

| Power (HP- kW) | 3 – 2.2 |

| Vibration Levels | 4.4 |

| Maximum Cutting Depth (mm) | 3 |

| Vacuum Take off Diameter (mm) | 50 |

| Vibration at Handlebar (Electric & Pneumatic Motor) | |

| TCT Cutters (concrete) | 4.4m/s2 (K=+1.43m/s2) |

| TCT Cutters (steel) | 2.9m/s2 (K=+0.63m/s2) |

| Star Cutters (concrete) | 3.7m/s2 (K=+0.7m/s2) |

| Star Cutters (steel) | 3.8m/s2 (K=+0.98m/s2) |

| Beam Cutters (concrete) | 4.8m/s2 (K=+0.79m/s2) |

| Beam Cutters (steel) | 5.4m/s2 (K=+0.9m/s2) |

| Milling Cutters (concrete) | 7.0m/s2 (K=+1.41m/s2) |

| Milling Cutters (steel) | 4.8m/s2 (K=+1.3m/s2) |

| Wire Brush (concrete) | 2.4m/s2 (K=+0.92m/s2) |

| Wire Brush (steel) | 3.8m/s2 (K=0.79m/s2) |

| Part Number | 320.2406T |

| Height (mm) | 900 |

| Width | 350 |

| Length (mm) | 900 |

| Cutting width (Dependent on Cutters) (mm) | 195 |

| Cutter head speed | 1650 |

| Working distance from wall | 55mm |

| Weight (Dependent on power unit) | 71 |

| Voltage (V) | 400 |

| Cycle (Hz) | 50 / 60 |

| Plug Size | 16 Amp 5 Pin |

| Cable Size (mm) | Min 2.5 core |

| Cable Length (m) | 30 |

| Power (HP- kW) | 3 – 2.2 |

| Vibration Levels | 4.4 |

| Maximum Cutting Depth (mm) | 3 |

| Vacuum Take off Diameter (mm) | 50 |

| Vibration at Handlebar (Electric & Pneumatic Motor) | |

| TCT Cutters (concrete) | 4.4m/s2 (K=+1.43m/s2) |

| TCT Cutters (steel) | 2.9m/s2 (K=+0.63m/s2) |

| Star Cutters (concrete) | 3.7m/s2 (K=+0.7m/s2) |

| Star Cutters (steel) | 3.8m/s2 (K=+0.98m/s2) |

| Beam Cutters (concrete) | 4.8m/s2 (K=+0.79m/s2) |

| Beam Cutters (steel) | 5.4m/s2 (K=+0.9m/s2) |

| Milling Cutters (concrete) | 7.0m/s2 (K=+1.41m/s2) |

| Milling Cutters (steel) | 4.8m/s2 (K=+1.3m/s2) |

| Wire Brush (concrete) | 2.4m/s2 (K=+0.92m/s2) |

| Wire Brush (steel) | 3.8m/s2 (K=0.79m/s2) |

| Part Number | 320.2416T |

| Height (mm) | 900mm |

| Width | 350 |

| Length (mm) | 900 |

| Cutting width (Dependent on Cutters) (mm) | 195 |

| Cutter head speed | 1650 |

| Working distance from wall | 55 |

| Weight (Dependent on power unit) | 71 |

| Voltage (V) | 110 |

| Cycle (Hz) | 50 |

| Plug Size | 32 Amp 3 pin |

| Transformer Size | 3Kva |

| Cable Size (mm) | 2.5-4 core |

| Cable Length (m) | 15-30m |

| Power (HP- kW) | 3 – 2.2 |

| Vibration Levels | 4.4 |

| Maximum Cutting Depth (mm) | 3 |

| Vacuum Take off Diameter (mm) | 50 |

| Vibration at Handlebar (Electric & Pneumatic Motor) | |

| TCT Cutters (concrete) | 4.4m/s2 (K=+1.43m/s2) |

| TCT Cutters (steel) | 2.9m/s2 (K=+0.63m/s2) |

| Star Cutters (concrete) | 3.7m/s2 (K=+0.7m/s2) |

| Star Cutters (steel) | 3.8m/s2 (K=+0.98m/s2) |

| Beam Cutters (concrete) | 4.8m/s2 (K=+0.79m/s2) |

| Beam Cutters (steel) | 5.4m/s2 (K=+0.9m/s2) |

| Milling Cutters (concrete) | 7.0m/s2 (K=+1.41m/s2) |

| Milling Cutters (steel) | 4.8m/s2 (K=+1.3m/s2) |

| Wire Brush (concrete) | 2.4m/s2 (K=+0.92m/s2) |

| Wire Brush (steel) | 3.8m/s2 (K=0.79m/s2) |

| Part Number | 320.2412T |

| Height (mm) | 900 |

| Width | 350 |

| Length (mm) | 900 |

| Cutting width (Dependent on Cutters) (mm) | 195 |

| Cutter head speed | 1528 |

| Working distance from wall | 55mm |

| Weight (Dependent on power unit) | 62 |

| Power (HP- kW) | 3.5 – 2.6 |

| Vibration Levels | 4.4 |

| Air Consumption (lps – cfm) | 78 -165 |

| Maximum Cutting Depth (mm) | 3 |

| Vacuum Take off Diameter (mm) | 50 |

| Vibration at Handlebar (Electric & Pneumatic Motor) | |

| TCT Cutters (concrete) | 4.4m/s2 (K=+1.43m/s2) |

| TCT Cutters (steel) | 2.9m/s2 (K=+0.63m/s2) |

| Star Cutters (concrete) | 3.7m/s2 (K=+0.7m/s2) |

| Star Cutters (steel) | 3.8m/s2 (K=+0.98m/s2) |

| Beam Cutters (concrete) | 4.8m/s2 (K=+0.79m/s2) |

| Beam Cutters (steel) | 5.4m/s2 (K=+0.9m/s2) |

| Milling Cutters (concrete) | 7.0m/s2 (K=+1.41m/s2) |

| Milling Cutters (steel) | 4.8m/s2 (K=+1.3m/s2) |

| Wire Brush (concrete) | 2.4m/s2 (K=+0.92m/s2) |

| Wire Brush (steel) | 3.8m/s2 (K=0.79m/s2) |

Accessories & Consumables

| Image | Part Number | Description | Further Information |

|

Trelawny: 320.002H IMPA: 59.22.49 ISSA: 55.096.16 |

Heavy Duty Drum Complete with 12mm shafts |

Fitted as standard on all TFP200 machines |

|

Trelawny: 320.0020 IMPA: 59.22.49 ISSA: 55.096.18 |

Cutter Shafts 12mm Diameter |

4 pieces required per drum |

|

Trelawny: 320.5500 IMPA: 59.22.41 ISSA: 55.096.10 |

Tungsten Carbide Tipped Cutters 5 tips |

80 pieces required per drum |

|

Trelawny: 320.7006 | Tungsten Carbide Tipped Cutters 6 tips |

80 pieces required per drum |

|

Trelawny: 320.3658 IMPA: 59.22.42 ISSA: 55.096.11 |

Star Cutters | 208 pieces required per drum |

|

Trelawny: 320.5120 IMPA: 59.22.43 ISSA: 55.096.12 |

Beam Cutters | 264 pieces required per drum |

|

Trelawny: 320.4140 | Spacers Used to create a gap in between TCT cutters |

88 pieces required per drum – TCT |

|

Trelawny: 320.9622 | Twisted Knot Wire Brush Refill | 21 pieces required per drum |

|

Trelawny: 320.9612 | Crimped Wire Brush Refill | 14 Pieces required per drum |

|

Trelawny: 320.1020ST | Drum Assembly TCT Cutters |

Consists of drum, 4 12mm shafts, 80 TCT cutters & 88 spacers |

|

Trelawny: 320.1020SS | Drum Assembly Star Cutters |

Consists of drum, 4 12mm shafts, 80 TCT cutters & 88 spacers |

|

Trelawny: 320.1020SB | Drum Assembly Beam Cutters |

Consists of drum, 4 12mm shafts & 208 star cutters |

|

Trelawny: 320.9620 IMPA: 59.22.45 ISSA: 55.096.13 |

Drum Assembly Twisted Knot Wire Brush |

Consists of drum & 21 twisted wire brush segments |

|

Trelawny: 320.9610 IMPA: 59.22.44 ISSA: 55.096.14 |

Drum Assembly Crimped Wire Brush |

Consists of drum & 14 crimped wire brush segments |

| Image | Part Number | >Description |

|

Trelawny: 669.3121

IMPA: N/A ISSA: N/A |

110v Power Cable

20m length |

|

Trelawny: 669.3122

IMPA: N/A ISSA: N/A |

230v Power Cable

20m length |

|

Trelawny: 669.3124

IMPA: N/A ISSA: N/A |

440v Power Cable

20m length |

|

Trelawny: 843.0752

IMPA: N/A ISSA: N/A |

¾’’ air hose

Complete with couplings 15m length |

Additional information

| ATEX | aa, bb |

|---|