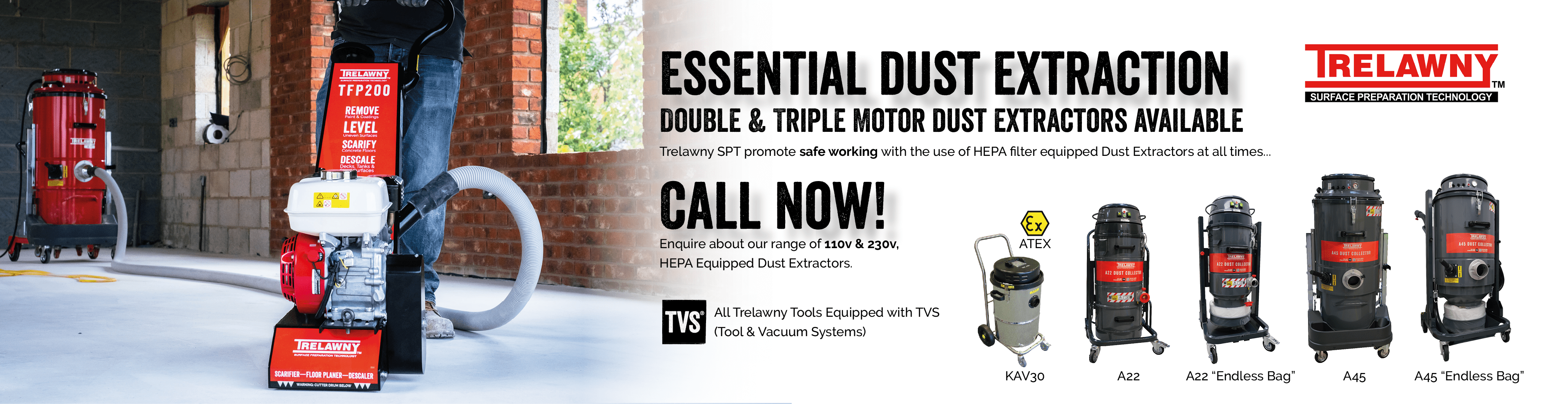

Featured Products

Team Trelawny

Our dedicated team enables Trelawny to continuously develop innovative products and a strong distribution network to support our global customers. Thanks to the knowledge and expertise gained since its inception. Trelawny is established today as a very reputable and highly marketable name synonymous with quality products.

Trelawny’s experienced staff are always pleased to advise customers on any technical or application-related requirements. The Trelawny Brand Center provides professional training, demonstration, and hands-on experience for its current range of products.